|

Tel: +86-755-23247978 MP/WhatsApp: +86-13760431543 Email: aaron@cxcolor.net |

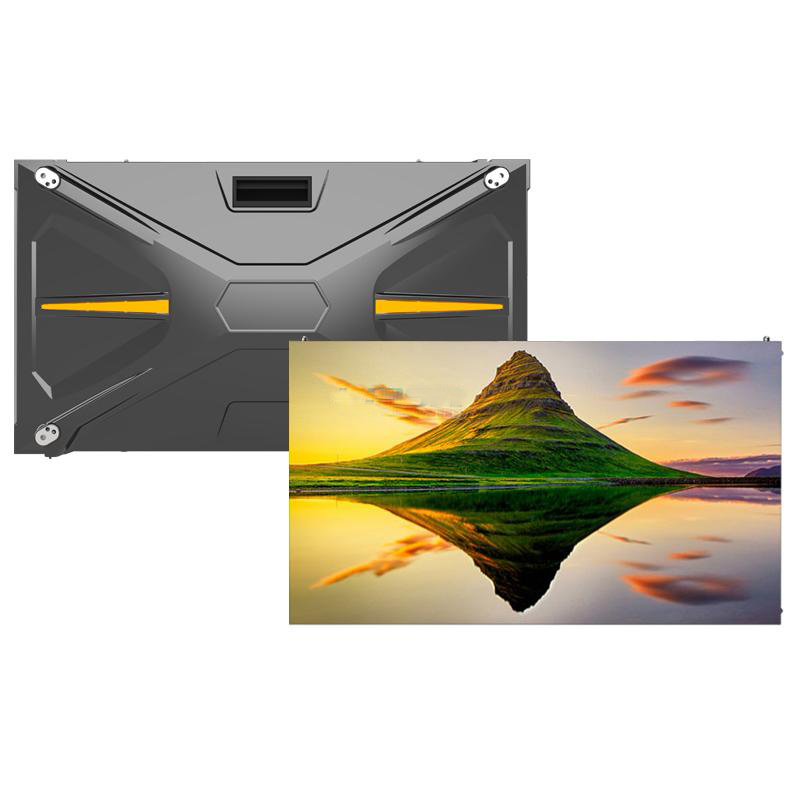

What is COB-LED displayIssuing time:2018-03-27 00:00 1. What is a COB display? COB and SMD are a kind of LED packaging method, but the difference is that SMD is called surface mount packaging technology, which means that the wick is welded one by one to the PCB board to make a unit board; and COB is to integrate the light emitting chip PCB board is not soldered one by one like SMD.

The COB display is an LED display composed of display modules made using COB technology and is called a COB display. 2. Main features of COB display. Due to its unique packaging method, the COB display has the following characteristics: mass production, small display pitch, good luminescence, and good anti-collision and waterproof characteristics. 3. The main difference between COB and smd. SMD light source concept SMD light source refers to surface-mounted light-emitting diodes, with a large light-emitting angle, up to 120-160 degrees, compared with early plug in packaging has high efficiency, good precision, low virtual soldering rate, light weight, small size and other advantages. The concept of COB light source COB light source means that the chip is directly packaged on the entire substrate, that is, the N chips are integrated and packaged on the inner substrate. It is mainly used to solve the problem of manufacturing high-power LED lights with low-power chips. It can disperse chip heat dissipation, improve light efficiency, and improve the glare effect of LED lights. The COB light flux density is high, the glare is less and the light is softer, and a uniformly distributed light surface is emitted. The relative advantages of COB are: Manufacturing efficiency advantage The production process of COB packaging is basically the same as the traditional SMD production process, and the efficiency of SMD packaging is basically equivalent in the process of solid crystal bonding and wire bonding. The product is much higher, the traditional SMD seal Installation labor and manufacturing costs account for approximately 15% of the material cost, COB packaging labor and manufacturing costs account for approximately 10% of the material cost, using COB packaging, labor and manufacturing costs can be saved by 5%. |